Home » Construction » Spray Foam Insulation – Is it a Worthy Investment in Pakistan?

Home insulation is something that many people in Pakistan are now investing in while developing their homes. It greatly helps with reducing the air-conditioning costs and also keeps your home at a controlled temperature throughout the year. With the kind of extreme weather conditions we face, home insulation is undoubtedly an excellent long-term investment during home construction. Speaking of which, made out of polyurethane, spray foam insulation goes a long way in serving this purpose.

Since a lot hasn’t been spoken in Pakistan after spray foam insulation, we took the liberty of compiling some of the best features of this insulation. And, in this blog, we will mainly study four things about polyurethane sprays:

- Types of Spray Foam Insulations in Pakistan

- Uses of Spray Foam Insulation

- Pros and Cons of Spray Foam Insulation

- Cost of Spray Foam Insulation in Pakistan

Types of Spray Foam Insulations in Pakistan

Mainly depending on the category of the structures of a house, building, or office, there are two main types of spray foam insulations in Pakistan, according to their density:

- Closed-cell foam: Also known as high-density foam, this type of spray foam insulation has many benefits over traditional insulation methods. Although per board foot cost of closed-cell foam is higher than open-cell foam, it is known to resist bulk water, even during floods since it has a higher R-value* (6.0 per inch). The most interesting thing about closed-cell foam is that it can be applied and works at temperatures as low as -15 degrees Celsius.

- Open-cell foam: As the name suggests, open-cell foam is full of cells that aren’t completely compressed. Another way to put it is that the cells are left deliberately open to make the foam softer and flexible to apply. It is known as a low-density foam due to its lower R-value (3.5 per inch).

*R-Value: A foam’s R-value is its resistance value against the water flow, heat, and other such damages. It is also a parameter of judging how well they insulate a building.

As a general rule, all types of spray foam insulations are able to satisfy the insulation requirements for walls, floors, ceilings, and roofs, and for various weather conditions to some extent.

Uses of Spray Foam Insulation

We know for a fact that home insulation can make your house energy-efficient, and it is a handy tool for reducing electricity bills. However, it is also an effective way to reduce heat trapped in the house, while simultaneously creating sufficient protection against water leakage and seepage without damaging or disturbing the interior look of your home. In comparison with other methods of insulation, spray foam is a lightweight polymer since it is created by mixing Methylene Diphenyl Isocyanate (MDI) with a polyol. Hence, it has a high thermal resistance and a low thermal conductivity, which aids in controlling the temperature of a house in extreme weather.

Additionally, polyurethane insulation can be sprayed onto walls and roofs to protect any kind of structure not only from moisture but also from the harsh and unpleasant sound. While it can cut down electricity costs by as much as 50 percent, people also use it to fill in crawl spaces and uneven surfaces to create an air barrier.

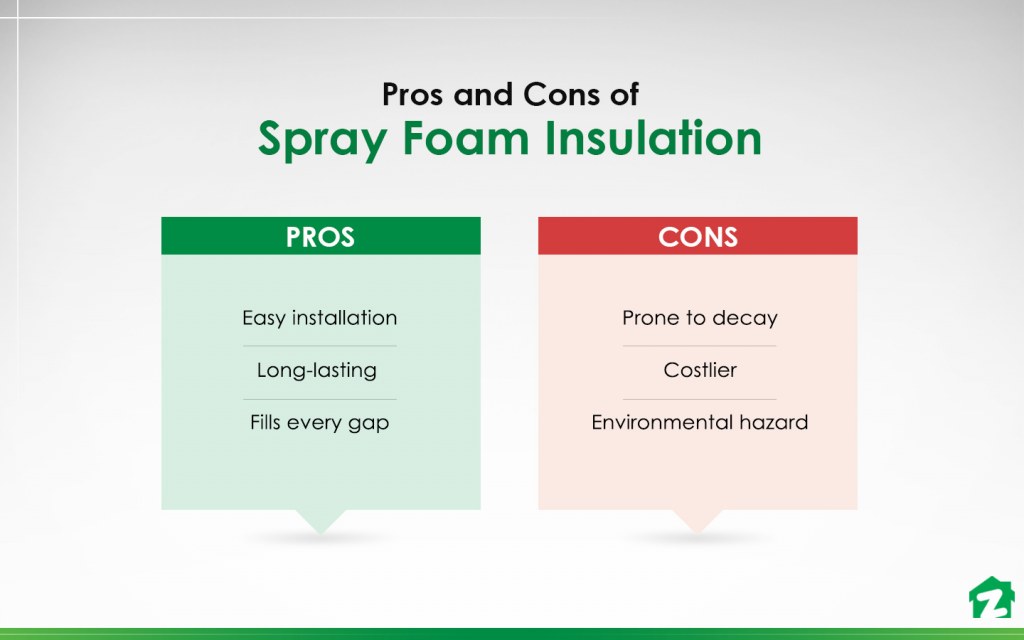

Pros and Cons of Spray Foam Insulation

Here are some pros and cons of spray foam insulation, so weigh these before making a decision.

Pros of Spray Foam Insulation

- Easy installation:Polyurethane spray foam is one of the easiest and minimally invasive methods of home insulation. It also takes little time and labour, as extensive structural changes are not required. With other insulation methods such as Jumbolon foam and such, multiple layers need to be installed, and if home insulation is added when the house is being lived in, it leads to significant monetary expenses and hassles.

- Long-lasting: According to experts, foam insulation is the most functional and remains effective for around at least 20 years if installed properly. Getting the foam from reputable companies ensures that you are using high-quality materials for longevity and effectiveness.

- Fills every gap: The best thing about polyurethane spray foam, according to most experts, is that it covers your home extensively by filling every gap and crevice. This material is made of polyurethane, with carefully built chemical structures, for the best performance possible. It expands to fill the empty gaps, making it practical and efficient.

Cons of Spray Foam Insulation

- Prone to Decay: The issue with polyurethane spray foam is that it may have to be reapplied if it gets too old or has not been installed properly. It is imperative that you have an expert install a spray foam insulation in your home or office, as any issues could cause it to leak, bubble, or deflate, rendering it ineffective.

- Costlier: Spray foam insulation, even though it can be installed without much of a hassle, is costlier than other home insulation methods – speaking in comparison with fibreglass, cellulose, and foam.

- Environmental impact: A huge issue with polyurethane spray foam is the fact that it is made of chemical compounds that are not biodegradable and can have a negative impact on the environment when disposed of. In addition, the spraying method itself can damage the environment. So, spray foam insulation may not be the best option for the environment.

So, these were some pros and cons of spray foam insulation. Consider these carefully and do your research before determining whether this is the best option for you. In any case, home insulation can be a good investment and save a lot of bills, so do keep that in mind. Now, let’s discuss the prices of spray foam insulation in Pakistan and in comparison with other methods of insulation.

Cost of Spray Foam Insulation in Pakistan

A small can of spray foam can be purchased for PKR 600 to PKR 800, which is handy to fill cracks, air-holes, and uneven surfaces within a house. However, the prices of spray foam insulation in Pakistan are decided according to per foot, which starts from PKR 100 per board foot, exclusive of labour cost, and depending on two things: the density and how well you negotiate. While PVC and other solid insulation sheets may cost as low as PKR 30 to PKR 50 per square foot.

If you buy a professional spray foam expanding polyurethane applicator, it can cost you around PKR 3 thousand to PKR 5 thousand, which will save you additional labour costs, while the price of an imported quality can of 5 kg is under PKR 30 thousand. Now, it is completely up to you if you are feeling nifty and want to take charge by doing it yourself!

If you have any questions or queries, get in touch with us at blog@zameen.com or leave a message on our Facebook page! Subscribe to Zameen Blog for more tips on home construction and renovation.

Comments are closed.

Dear Shanzay,

u always come up with different and useful articles…thumbs up

Thank you for the feedback, do keep following the blog for even more useful and unique articles!

Thanks for reply, its my routine to read the articles shared by u guys.

I believe that ur study not only rely on the stuff available on Google etc, instead u also hve approach to experts.

A humble request….Would u plz write on natural ventilation system and energy efficient house, i just read some south/west winds to cool down a house, windows placement, east faced house etc. The article i m referring is by someone lives in west not from our area so there is a lot to know.